High Performance Medical Devices

Require Powerful Solutions

Battery design experience across diverse applications

At Inventus Power, we customize our lithium-ion battery and charging systems to help you meet a wide range of business needs. Whether your industrial device requires a battery system that is lightweight, fast-charging, intrinsically safe, or designed to operate in extreme temperatures, we have the experience and capabilities to deliver a power solution that exceeds performance expectations.

Our 60+ years of experience spans across a broad range of commercial and industrial applications, including:

Surgical Tools & Instruments

Medical Mobility

Exoskeleton

Infusion & Syringe Pumps

Cardiac & Rhythm Management

Patient Monitoring

Respiratory Care

Wound Therapy

Imaging

ECG

Scopes

Diagnostics

Choose the Best Power Source for Your Medical Device

Standard Battery Packs

Standard Battery Charger

Medical Power Supplies

Battery Connectors & Leads

Readers & converters

Standard Power Management Modules

Custom Battery Solutions

Custom Charging Solutions

Customized Battery Management and Power Management Systems

Regulatory-Compliant Power Solutions for Medical Devices

SES Power Advantage

Medical device battery solutions are not one-size-fits-all, and neither are designers and manufacturers of battery packs, chargers and power supplies. When choosing a power solutions supplier, it’s critical for OEMs to find a partner that offers innovation and has the experience and capabilities to design and manufacture safe and reliable power solutions.

Inventus Power has been developing battery packs for over 60 years and have been a critical partner to many major medical device manufacturers, specifically aiding in their transition from different battery chemistries as well as enabling the complete transition from corded devices to battery-operated ones.

SES In-House Electronic Design & Development Capabilities

At SES, we have a fully equipped in-house facility for electronic design, supported by a highly skilled team of engineers. Our team is organized into specialized divisions, including power electronics, embedded systems, and testing, enabling seamless end-to-end product development. This structured approach allows us to execute complex designs efficiently and entirely in-house, without dependence on external resources for any task.

To further enhance our capabilities, we utilize advanced simulation and analysis tools such as ANSYS. This enables us to digitally evaluate and validate designs at the concept stage, identifying potential faults and failures early in the process. As a result, our designs maintain a high level of reliability and are optimized for performance even before physical prototyping begins.

Our fast prototyping capability is a key strength, supported by a robust infrastructure that includes a wide inventory of diverse electronic components maintained in our warehouse. We also have comprehensive in-house assembly facilities, ranging from desktop to high-volume robotic soldering systems, including desktop pick-and-place to high-speed automated setups. This allows us to develop and test Battery Management Systems (BMS) entirely within our own facility.

Additionally, we have established partnerships with local accredited laboratories for pre-compliance testing, ensuring our prototypes meet regulatory requirements at the early stages of development. This end-to-end, in-house capability positions SES as a reliable and efficient partner for delivering high-quality, fully compliant battery system solutions.

In-House Mechanical Design, Prototyping & Tooling Capabilities

At SES, our expert mechanical engineering team is dedicated to the careful and precise design of the complete product structure. Leveraging advanced simulation tools such as ANSYS, we analyze mechanical strength, fitment, potential compliance risks, and failure points at the design stage — ensuring performance and reliability from the very beginning.

To support rapid development, we have an in-house SLS 3D printing facility, allowing us to quickly prototype mechanical components without relying on external vendors. This significantly reduces our development cycle and enables fast design validation.

Our comprehensive in-house tooling infrastructure includes advanced CAD/CAM software, along with sophisticated Philips and HAAS CNC machines for high-precision mould making. We also operate our own injection moulding facility, ensuring complete control over the tooling and manufacturing process.

This end-to-end in-house capability gives us a distinct advantage in reducing product development time, enhancing flexibility, and maintaining the highest standards of quality and consistency.

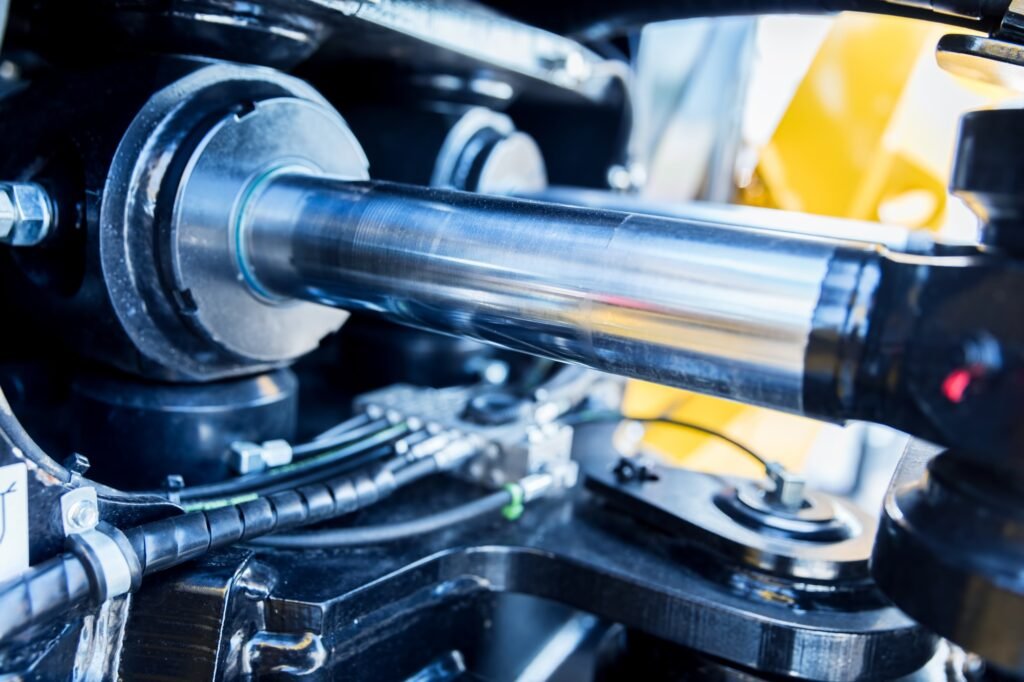

High-Volume Manufacturing with Critical Charge-Discharge Testing Capabilities

SES™ operates state-of-the-art manufacturing facilities located in Saha and Ambala Cantt. The company owns three plants with a combined area of over 40,000 sq. ft., offering capabilities in high-volume production, advanced design, modern tooling, laboratory testing, and inventory management. SES also features in-house BMS design, automated soldering systems, and an injection Mold tooling facility.

In addition, SES conducts essential cell-level testing, including charge and discharge cycles—an important process to ensure products perform reliably under extreme conditions. Recognizing the critical role of such testing in product quality, SES maintains substantial inventory levels to meet demand without compromising on rigorous testing standards.

Driving Product Innovation Through Industry 4.0 and Process Excellence

At SES™, we actively pursue Industry 4.0 principles, ensuring smart, data-driven product development and quality management. Our process begins at the design stage, where we prepare complete assembly drawings and detailed Bills of Materials (BOMs) for each product. Quality assurance is embedded at every stage – including inward material inspection, in-process quality checks, final product testing, and pre-dispatch evaluations.

Each product is thoroughly documented through dedicated technical files, capturing all quality and design parameters. As of December 2024, we have developed and documented over 600 unique products under this rigorous system. Our structured approach enables the development of 2 to 3 new products every month, ensuring consistent innovation and uncompromised quality.